-

DeWalt 20V MAX 14 Guage Swivel Head Double Cut Shears

The DeWalt 20V MAX 14 Guage Swivel Head Double Cut Shears

are used to cut sheet metal, and other light-duty materials like aluminum and mild steel. They are useful for making straight cuts and curves with minimal distortion, and are used for building ductwork and plenums, cutting notches in sheet metal, and cutting long panels. -

DeWalt 20V MAX 4.5”/5” Trigger Switch Angle Grinder

With tool-free wheel removal and guard adjustments, this DeWalt 20V MAX 4.5″/5″ Grinder allows for quick adjustments and positioning. The Quick-Change™ wheel release, a convenient trigger switch with lock off button offers productivity for fast wheel changes. Compatible with 20V MAX batteries and chargers, this cordless product can be added to your existing lineup.

-

DeWalt 20V MAX 4.5″ Variable Speed Paddle Switch Grinder

Complete a variety of jobs with the 20V MAX 4 1/2 in. – 5 in. Variable Speed Paddle Switch Grinder. As part of our most powerful line of 20V MAX Angle Grinders, this tool allows the user to adjust wheel speed to match the needs of a wide range of applications. This grinder delivers power for tough jobs and is equipped with PERFORM & PROTECT™ features like the ANTI-ROTATION System.

-

DeWalt 20V MAX XR 4.5″ Slide Switch Angle Grinder

Experience Power™ on challenging jobs with the DeWalt 20V MAX XR® 4.5″ Slide Switch Small Angle Grinder with Kickback Brake. As a part of the PERFORM & PROTECT™ line of products, this tool is equipped with KICKBACK BRAKE™ which engages with maximum force to stop the wheel when a pinch, stall, or bind-up is detected. This grinder is a part of the expanding 20V MAX system and is compatible with all 20V MAX batteries.

-

Tenryu 14″ Blade for Picture Framing

Select grade of carbide tip for better performance.

Large European style tips for longer life.

Heavy, European plate style resists deflection during cutting.

Resin bond, laser slots to absorb and eliminate vibration to produce a cleaner, quieter, more efficient cut.

Excellent blade life.Diameter: 14″

Teeth: 110

Arbor: 5/8″

Style: ATBR

Kerf: .118″

Blade: .087″

Rake: -3

Special Use: Picture Framing in wood with Double Miter Saw. -

Makita Four Port Charger, 18V LXT

The 18V Lithium-Ion 4-Port Charger (model DC18SF) offers several advantages for cordless tool users. It has a compact size that is ideal for job site or shop use, and will accommodate up to four 18V Lithium-Ion batteries at one time for increased efficiency and less downtime.

The DC18SF will charge two 18V LXT® 3.0 Ah batteries in 60 minutes, and four 18V LXT® 3.0 Ah batteries in 120 minutes. The charger will also accommodate 18V Compact Lithium-Ion 2.0 Ah batteries, with a 50-minute charge time for two batteries and up to 100 minutes for four batteries. It is compatible with all Makita 18V Lithium-Ion slide-style batteries.

-

Makita Single Port Automotive Charger, 18V LXT

The Makita Optimum automotive charger is designed for anyone that needs to be able to charge their LXT batteries on the go, perfect for tradesmen and other professional that can use the down time to re-charge their batteries using conventional 12V sockets.

The Optimum Charger offers key advantages for Makita 18V Lithium-Ion cordless tool users. The exclusive built-in fan cools the battery by forcing air through the battery’s air vents during the charging process for faster charging. The charger communicates with the battery’s built-in chip throughout the charging process to optimize battery life by actively controlling current, voltage and temperature. The result is category-leading battery charge times, which means the battery spends more time working and less time sitting on the charger.

-

Makita Dual Port Rapid Charger, 18V LXT

Makita LXT® is the world’s largest cordless tool system powered by 18V Lithium-Ion slide-style batteries. At the heart of the LXT® System is the 18V LXT® Lithium-Ion battery and the efficient Rapid Optimum Charger. The 18V Lithium-Ion Dual Port Rapid Optimum Charger (DC18RD) charges two batteries at the same time, giving tool users unparalleled charging efficiency so their batteries spend more time working and less time sitting on the charger.

-

MAKITA SINGLE PORT RAPID CHARGER, 18V LXT

Makita LXT® is the world’s largest cordless tool system powered by 18V Lithium-Ion slide-style batteries. At the heart of the Makita 18V LXT® System is the efficient Rapid Optimum Charger.

The Rapid Optimum Charger offers key advantages for Makita 18V Lithium-Ion cordless tool users. The exclusive built-in fan cools the battery by forcing air through the battery’s air vents during the charging process for faster charging. The charger communicates with the battery’s built-in chip throughout the charging process to optimize battery life by actively controlling current, voltage and temperature. The result is category-leading battery charge times, which means the battery spends more time working and less time sitting on the charger.

-

Read MoreQuick View

Read MoreQuick ViewMakita 18V LXT Battery Series, w/ Star Protection

The Makita 18V LXT® Lithium-Ion battery charges faster and works longer than standard lithium-ion batteries, giving you and your cordless tools unmatched performance and productivity to take on the most demanding applications. The Makita line of 18V batteries combines more run time, with category-leading charge times, so they spend more time working and less time sitting on the charger. For added convenience, they also features an L.E.D. charge level indicator to monitor battery charge.

For improved tool performance and extended battery life, Makita created STAR Protection Computer Controls™. STAR Protection is communication technology that allows the tool and battery to exchange data in real time and monitor conditions during use to protect against overloading, over-discharging and overheating. The 18V LXT® battery series is compatible only with Star Protection tools, indicated by the Star Symbol™ and/or Yellow Battery Receiver under the tool. All current Makita tools sold at Thread Source are Star compatible.

There are five batteries available in the Makita 18V LXT lineup. Those are:

- BL1820B, 18V LXT 2.0Ah

- BL1830B, 18V LXT 3.0Ah

- BL1840B, 18V LXT 4.0Ah

- BL1850B, 18V LXT 5.0Ah

- BL1860B, 18V LXT 6.0Ah

-

Irwin 8 R Locking Sheet Metal Tool

The Irwin VISE-GRIP Original Locking Sheet Metal Tool, makes bending, forming, and crimping sheet metal easier than ever. It measures 8″ long, with a jaw width of 3-1/8 inches and throat depth of 1-3/4 inches. It locks to the work with a powerful grip, makes bread-pan corners, and can crimp and double crimp and stretch upholstery webbing. Constructed of high-grade heat-treated alloy steel for maximum toughness and durability, this metal bender also features the original locking mechanism that made VISE-GRIP famous. A turn screw adjusts pressure to fit work, and stays adjusted for repetitive use while the classic trigger release delivers maximum locking force.

-

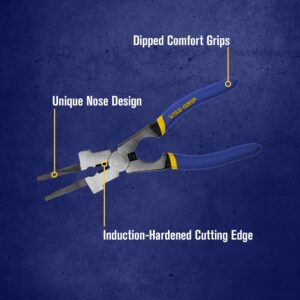

Irwin Vise-Grip 8″ MIG Pliers

Irwin 1873303 MIG Welding Pliers Features a specially-designed nose for efficient removal of welding spatter. The induction-hardened cutting edge stays sharp longer, while multiple jaws are available for drawing out wire and removing of installing tips and nozzles. Hammer designed for light welding gun maintenance. Spring-loaded for ease of use. Dipped grips for superior comfort. Backed by the Irwin Vise-Grip lifetime guarantee.

-

Tenryu 14″ Blade for Picture Framing

Select grade of carbide tip for better performance.

Large European style tips for longer life.

Heavy, European plate style resists deflection during cutting.

Resin bond, laser slots to absorb and eliminate vibration to produce a cleaner, quieter, more efficient cut.

Excellent blade life.Diameter: 14″

Teeth: 110

Arbor: 5/8″

Style: ATBR

Kerf: .118″

Blade: .087″

Rake: -3

Special Use: Picture Framing in wood with Double Miter Saw.