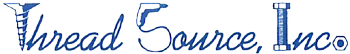

POWER-Skru Bolt Anchors

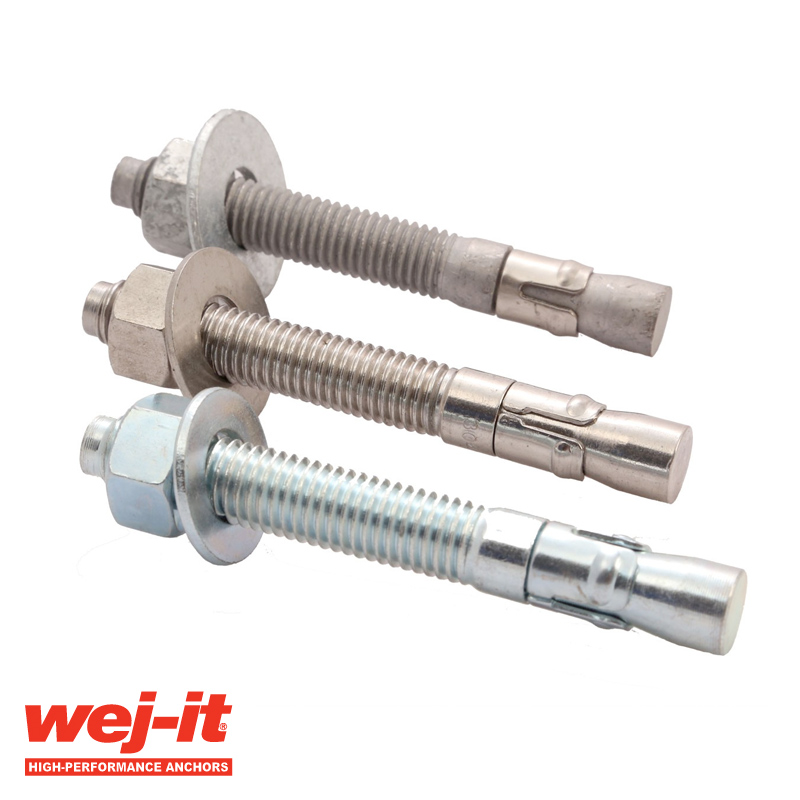

The POWER-Skru Bolt Anchor is a high-strength screw anchorwith self-taping threads that offer a unique undercutting design for anchoring into concrete and masonry. No secondary setting is needed. The POWER-Skru Bolt Anchor provides high-strength performance with low installation torque. A heavy-duty mechanically-galvanized finish is available to enhance corrosion resistance.

Can be used with almost any material, including:

- Racking

- Railing Sill

- Stadium Seating

- Tilt up Braces

- Formwork

- Anchoring Equipment

- Description

- Additional information

- Installation

- Tech Specs

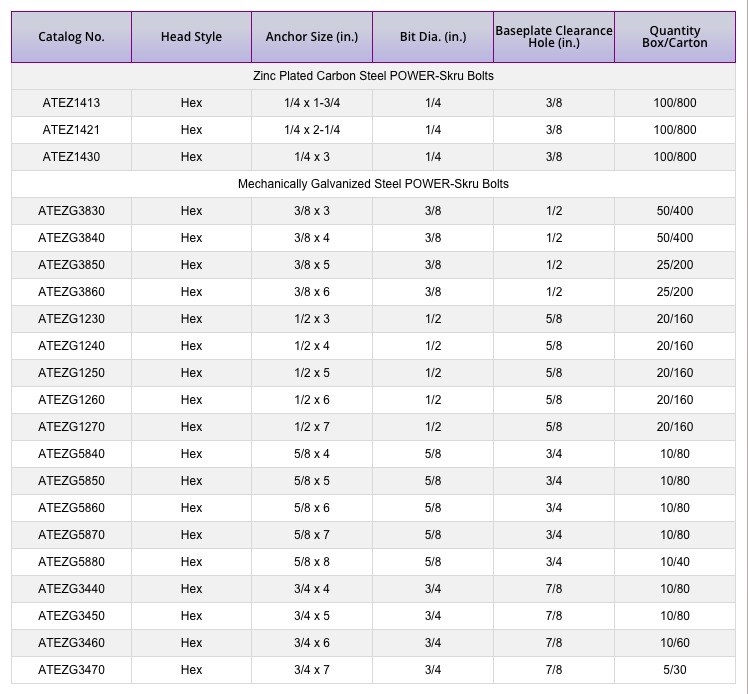

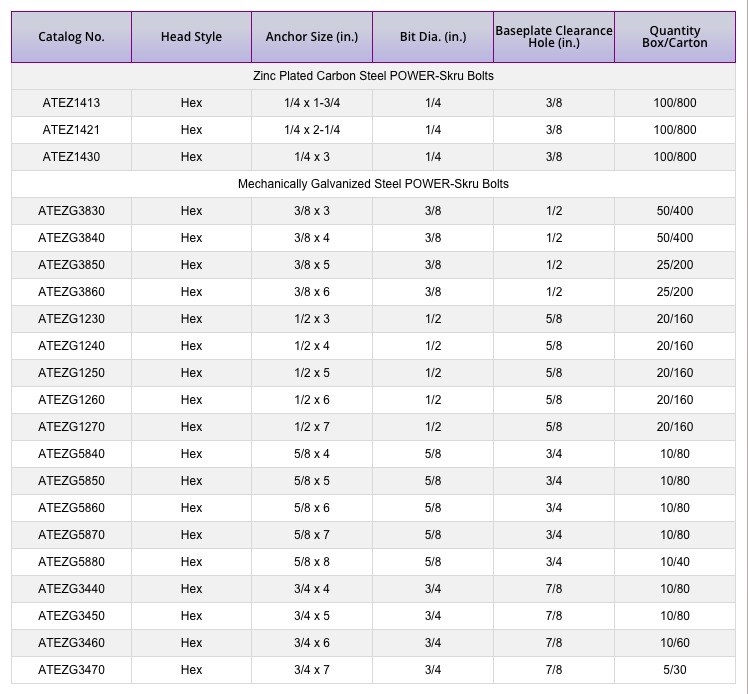

- Part Numbers

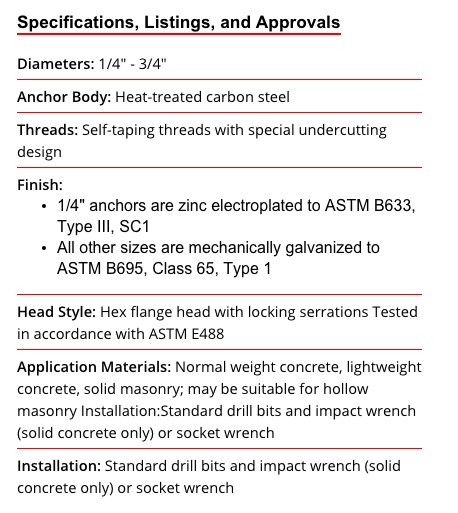

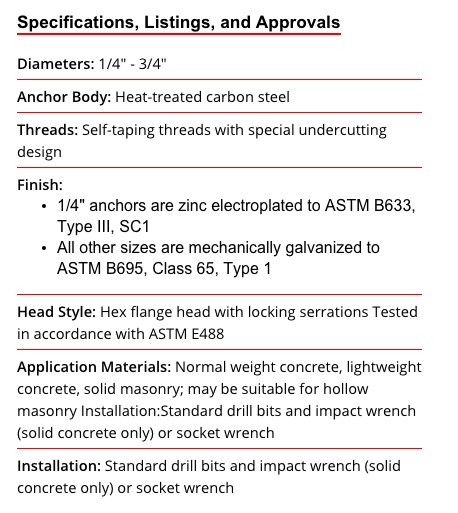

- Specifications and Approvals

- Downloads

Description

- Electroplated zinc or heavy-duty mechanically galvanized finish available

- Heat treatment provides surface and core hardness

- One-piece design with finished washer head

- Serrated head facilitates a positive lock between bolt and application surface for enhanced vibration resistance

- Hardened, self-tapping threads feature a revolutionary undercutting design

- Allows for immediate load application

- Reduces required installation torque

- Can be installed with an impact or socket wrench

- Can be removed and reinstalled

- Anchor length is stamped on head to ease identification pre- and post-installation

- Easier and faster installation than mechanical expansion anchors

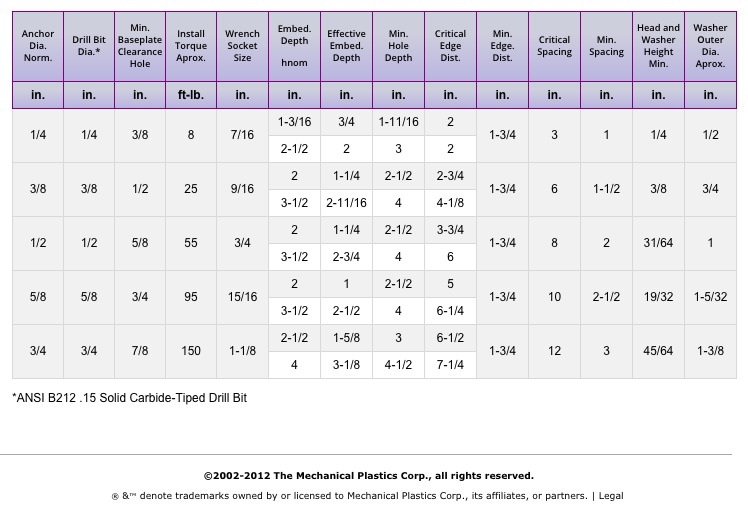

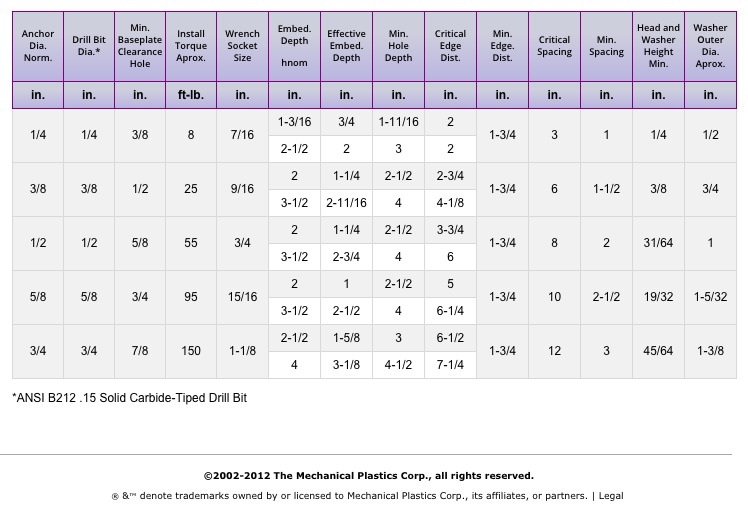

- Prepare hole with lower-cost ANSI B212.15 standard bit – no metric or off-size bits needed

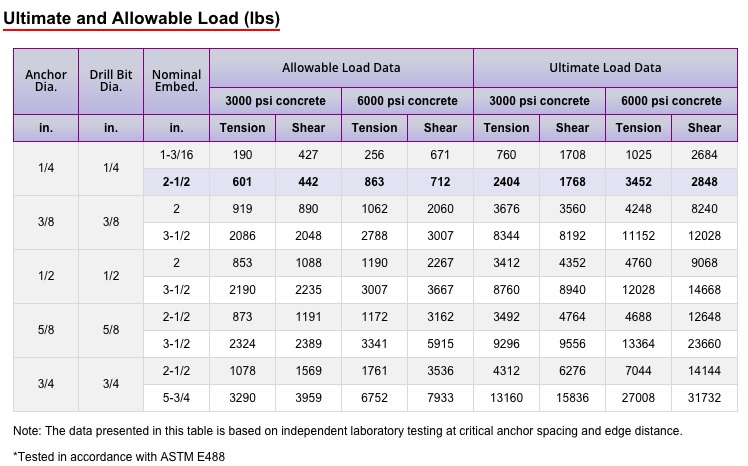

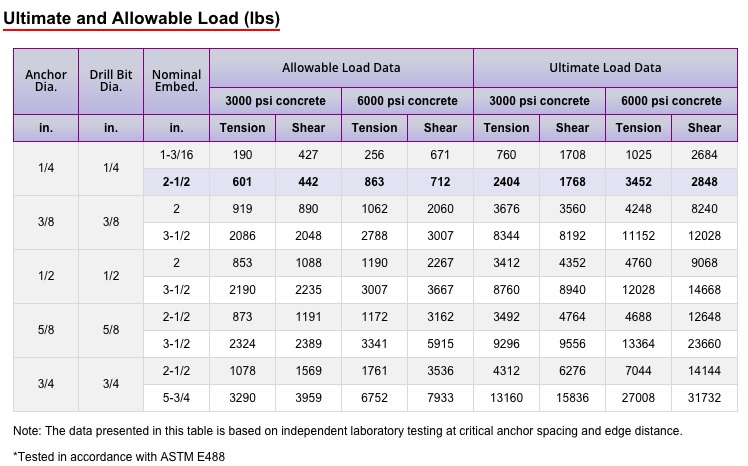

- Lower spacing and edge distance requirements than mechanical expansion anchors

Additional information

| Material | Galvanized Steel, Stainless Steel |

|---|---|

| Size | 1/4″ x 3″, 3/8″ x 1-3/4″, 3/8″ x 2-1/2″, 3/8″ x 3″, 3/8″ x 4″, 3/8″ x 5″, 1/2″ x 3″, 1/2″ x 4″, 1/2″ x 5″, 1/2″ x 6″, 1/2″ x 7″, 1/2″ x 8″, 5/8″ x 3″, 5/8″ x 4″, 5/8″ x 5″, 5/8″ x 6″, 5/8″ x 8″, 3/4″ x 4″, 3/4″ x 5″, 3/4″ x 6″, 3/4″ x 7″, 3/4″ x 8-1/2″ |

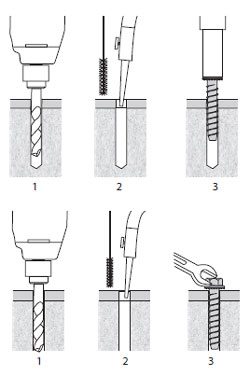

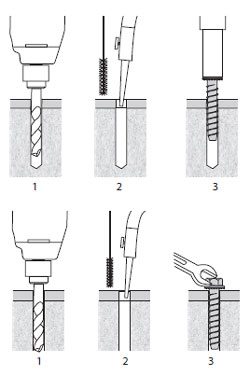

- Using the proper size carbide bit, drill a pilot hole at least one anchor diameter deeper than the desired anchor embedment.

- Blow out concrete dust.

- Using an electric impact wrench, or socket wrench, insert anchor into hole and tighten anchor until fully seated. If using an electric impact wrench, start on light torque setting to prevent over torturing or damaging threads.

- NOTE: Always wear safety glasses.

Installation in Concrete Block (CMU)

- NOTE: Do not use an impact wrench for installation into CMU walls.

- Using the proper size carbide bit, drill a pilot hole at least one anchor diameter deeper than the desired anchor embedment.

- Blow out concrete dust.

- Using a socket wrench insert anchor into hole and hand tighten anchor until fully seated.

- NOTE: Always wear safety glasses.

*To assure full load values, do not ream the hole or allow the drill bit to wobble. Use solid carbide-tipped drill bits meeting ANSI B212.15 diameter standards.