Hex Tap Bolts

The major distinguishing feature of hex tap bolts is that they are always fully threaded from under the head to the tip, no matter the size. Other features, such as chamfered point or washer bearing surface under the head, may be present, or may not. Tap bolts are meant to be used nuts to secure two objects together, but they also will fully seat into a tapped hole to secure one material to a base material.

They are available in Grade 2, Grade 5, and in Stainless Steel.

- Additional information

- Description

- Features

Additional information

| Grade | Grade 2, Grade 5 |

|---|---|

| Material Finish | Zinc, Stainless Steel 18-8 |

| Diameter | 1/4″, 5/16″, 3/8″, 7/16″, 1/2″, 5/8″, 3/4″, 7/8”, 1” |

| Length | 3/4″, 1″, 1-1/4″, 1-1/2″, 1-3/4″, 2″, 2-1/4″, 2-1/2″, 2-3/4″, 3″, 3-1/2″, 4″, 4-1/2″, 5″, 5-1/2″, 6″ |

The major distinguishing feature of hex tap bolts is that they are always fully threaded from under the head to the tip, no matter the size. Other features, such as chamfered point or washer bearing surface under the head, may be present, or may not. Tap bolts are meant to be used nuts to secure two objects together, but they also will fully seat into a tapped hole to secure one material to a base material.

They are available in Grades 2 and 5, or in Stainless Steel.

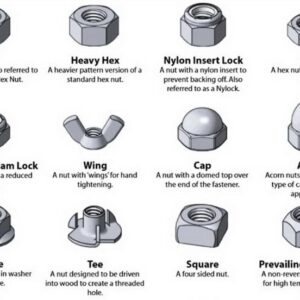

Every site that tries to explain the distinction between hex cap screws and hex tap bolts has the same problem: the two items are almost identical. Some features are always present on one style, but may still be seen on the other. Here are some examples:

- Washer bearing surface under the head: Hex cap screws have a "built-in" washer under the hex head. This ensures a smooth and flat surface to correctly tighten the bolt down onto the material it is inserted into, and prevents marring that material with the corners of the bolt head. This is also why hex cap screws are described as being "tightened by turning the head", and hex tap bolts are described as being "tightened by turning a nut". But hex tap bolts can also have that same built-in washer surface.

- Chamfered end: Hex cap screws have a slight chamfer on the end. It isn't a full "pointy end" as in sheet metal screws, but is just enough to make it easier to insert the end into a hole that's the same diameter as the screw. Hex tap bolts usually have a flat-cut end with no chamfer, but some have this feature too.

- Fully threaded: Hex tap bolts are always fully threaded from under the head to the end of the bolt. Hex cap screws usually have a shoulder area that is unthreaded, with the threads only extending a few inches up from the end. However, short hex cap screws are usually fully threaded just because of their short length. Also, some longer hex cap screws are specifically made as fully threaded, with their other required features as mentioned above.

The real distinction between hex cap screws and hex tap bolts is with the official specifications that define each. Hex cap screws are made in accordance with ASME B18.2.1 1996 and SAE J-429 - 1999, and hex tap bolts are made in accordance with IFI-199.