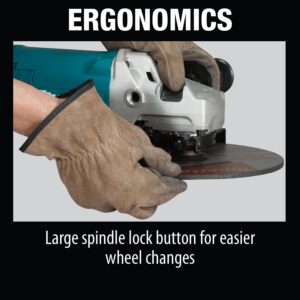

Glass Sanding Disc, 5″

Black silicon carbide is harder than aluminum oxide, and is generally used for the abrasives and ceramic industries. The only two common abrasive materials harder than SiC are diamonds and boron carbide. Silicon Carbide is special in the way it breaks down. As it breaks down into smaller particles, the media will expose new, sharp edges. Therefore, as the media breaks down, it will create a “working blend” of various sized particles. This allows for effective surface cleaning/polishing.

These sanding discs use these attributes of silicon carbide to polish glass, as well as ceramics, and stone.

- Additional information

- Description

- Abrasive Materials and Applications

- Data Sheets & Downloads

Additional information

| Size & Grit | 5″ – 80, 5″ – 120, 5″ – 220 |

|---|

Black silicon carbide is harder than aluminum oxide, and is generally used for the abrasives and ceramic industries. The only two common abrasive materials harder than SiC are diamonds and boron carbide. Silicon Carbide is special in the way it breaks down. As it breaks down into smaller particles, the media will expose new, sharp edges. Therefore, as the media breaks down, it will create a "working blend" of various sized particles. This allows for effective surface cleaning/polishing.

These sanding discs use these attributes of silicon carbide to polish glass, as well as ceramics, and stone.

Silicon Carbide

Aggressive cutting action for a clean, smooth finish. Excellent on titanium, fiberglass, plastics, and masonry products.

Safety Data Sheet (SDS), Vitrified Bond Abrasives

Safety Data Sheet (SDS), Resin Bonded Abrasives

Safety Data Sheet (SDS), Flap Disc Abrasives